Products

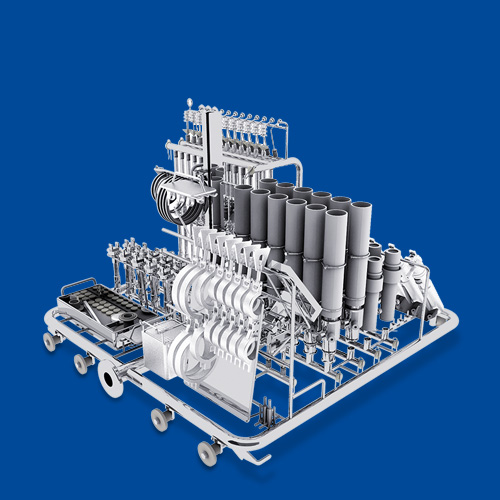

cGMP-compliant cleaning- and sterilizing systems with the highest data integrity. Highest process, user and environmental safety thanks to our innovative operating system.

Belimed Life Science

Have you ever asked yourself how to ensure that no dangerous viruses or bacteria escape from laboratories or pharmaceutical companies? Belimed Life Science AG takes care of this with its process solutions for cleaning, desinfection and sterilisation. The customer-specific systems ensure that products in the pharmaceutical, biopharmaceutical, laboratory and cosmetics industries are sterile and clean. In addition to these systems, we also offer the appropriate process solutions, upgrades, services and accessories to guarantee repeatable processes. With our two production sites in Sulgen (CH) and Grosuplje (SI) and our worldwide service network, we can react flexibly and quickly to customer requirements. With over 250 specialists, we enjoy an excellent reputation worldwide and our products are among the best in the world.

Fairs and events

INNOVATRIX

Date: November 9. – 10, 2023 | Location: Vienna | Land: Austria | Website

2023 ISPE Annual Meeting & Expo

Date: November 15 – 18, 2023 | Location: Las Vegas | Country: USA | Website

CPHI-PMEC 2023

Date: November 28 – 30, 2023 | Location: Delhi | Country: India | Website

2023 ISPE Pharma 4.0™ and Annex 1 Conference

Date: December 11 – 12, 2023 | Location: Barcelona | Country: Spain | Website

Pharma Congress

Date: March 19 – 20, 2024 | Location: Wiesbaden | Country: Germany | Website

Interphex

Date: April 16 – 18, 2024 | Location: New York | Country: USA | Website

Cophex

Date: April 23 – 26, 2024 | Location: Goyang | Country: Southkorea

Achema

Date: June 10 – 14, 2024 | Location: Frankfurt | Country: Germany | Website

FCE Pharma

Date: June 13 – 15, 2024 | Location: Sao Paulo | Country: Brasil | Website

CPHI Thailand

Date: July 10 – 12, 2024 | Location: Bangkok | Country: Thailand | Website

Vacancies at Belimed Life Science

Interested in hot steam and purest water?

For us, everything revolves around the medium of water, which we use in its purest form not only for cleaning but also for sterilization. Exciting processes and innovative plants are our daily challenges. Become part of our worldwide team and apply for a job.

PFAS - What does this mean for our systems?

The effects of potential PFAS regulation by the European Chemicals Agency (ECHA) are currently the subject of intense debate. We would like to give you a brief overview of the current status of developments.

Applications / Reference Projects

Customized quality solutions - that is our guiding principle. Our strengths are maximum flexibility, minimum risk of change and fast implementation.

The plants are adapted to your specific local conditions and comply with worldwide specifications. Learn more about what we have already realized!

Services

Full life cycle management from the initial concept idea to production, qualification, maintenance, service and retrofitting - all from one source. We offer a local service network to guarantee the highest machine uptime. In addition, we offer retrofits/upgrades so you always use "state of the art" technology.